From Manufacturing to Organisation

We always pay special attention to quality in our customer service, production, testing, logistics and other processes. We manage a wide range of comprehensive deliveries from manufacturing to organisation.

Quality factors are carefully tuned

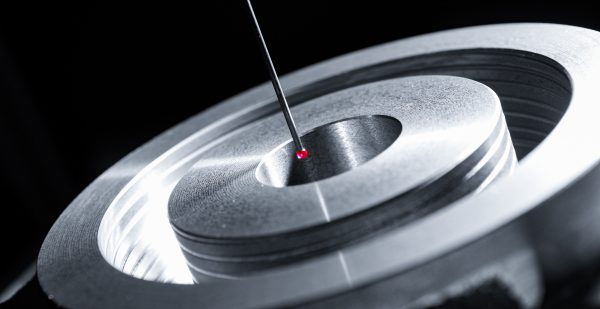

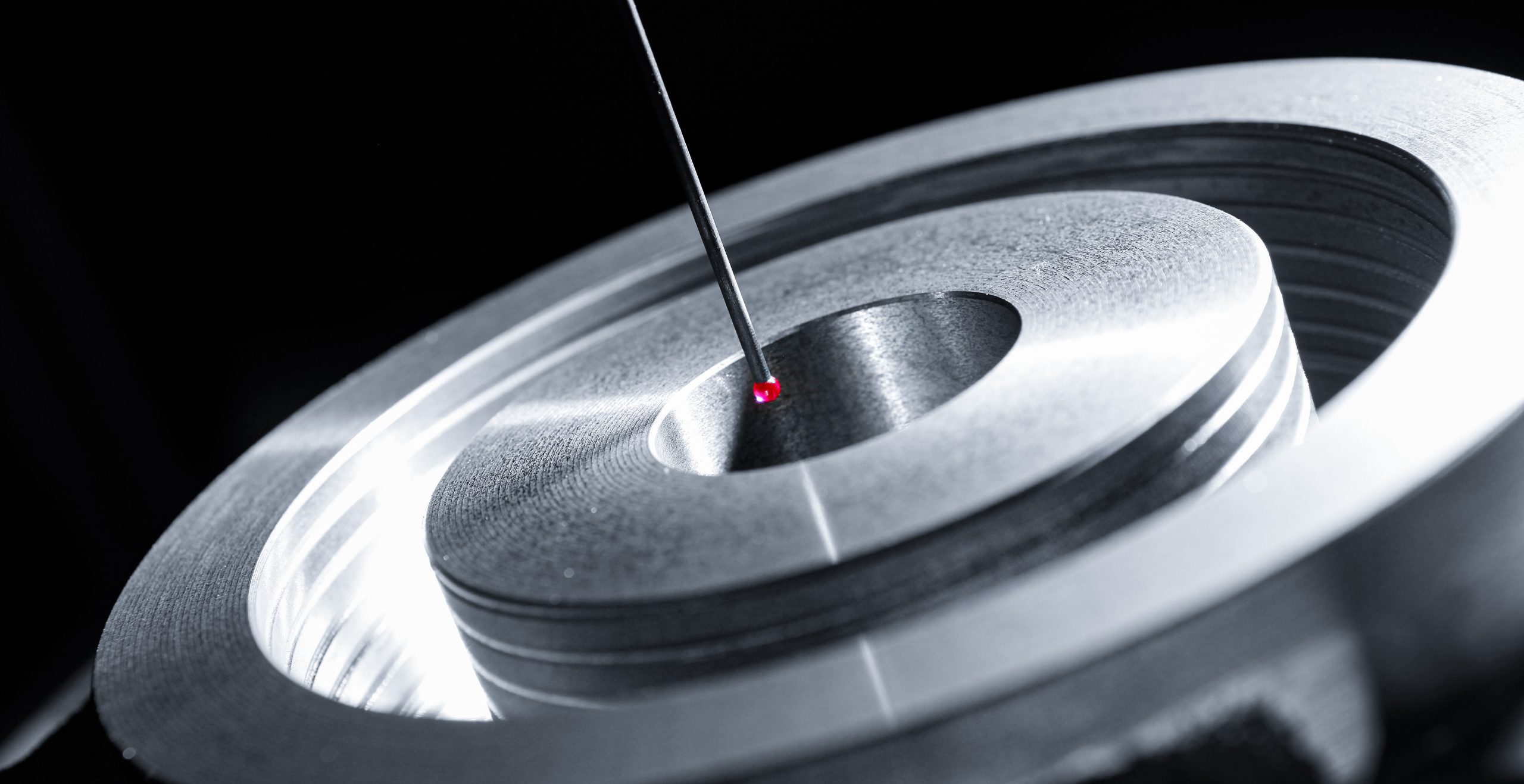

Our methods meet industry requirements and standards. In addition, we invest heavily in the quality and development of our production machinery. We use modern and automated hardware, robotics, software and tools. In automated manufacturing, we utilize machine vision, among other things.

We also regularly develop and renew both our methods and our equipment. As part of our quality control system, we conduct comprehensive product testing at all stages of the production process.

High-quality production, for example:

- Mazak Integrex i Series Multifunction Machines and Horizontal Machining Centres

- A FMS system (including automatic storage and robotic charging cell)

- Zeiss T-Scan 3D Scanner

- Zeiss PiWeb analysis software (SPC, FPY, Cpk, etc.)

- Zeiss 3D measuring machines (Duramax and Accura)

- Electro technical measuring instruments (surge wave, mΩ–GΩ, HiPot, insulation resistance)

- 500 kW test field for testing electric motors

- PPAP (PSW, 8D, CTQ)

- ISO 9001 quality system

- ISO 14001 environmental management system